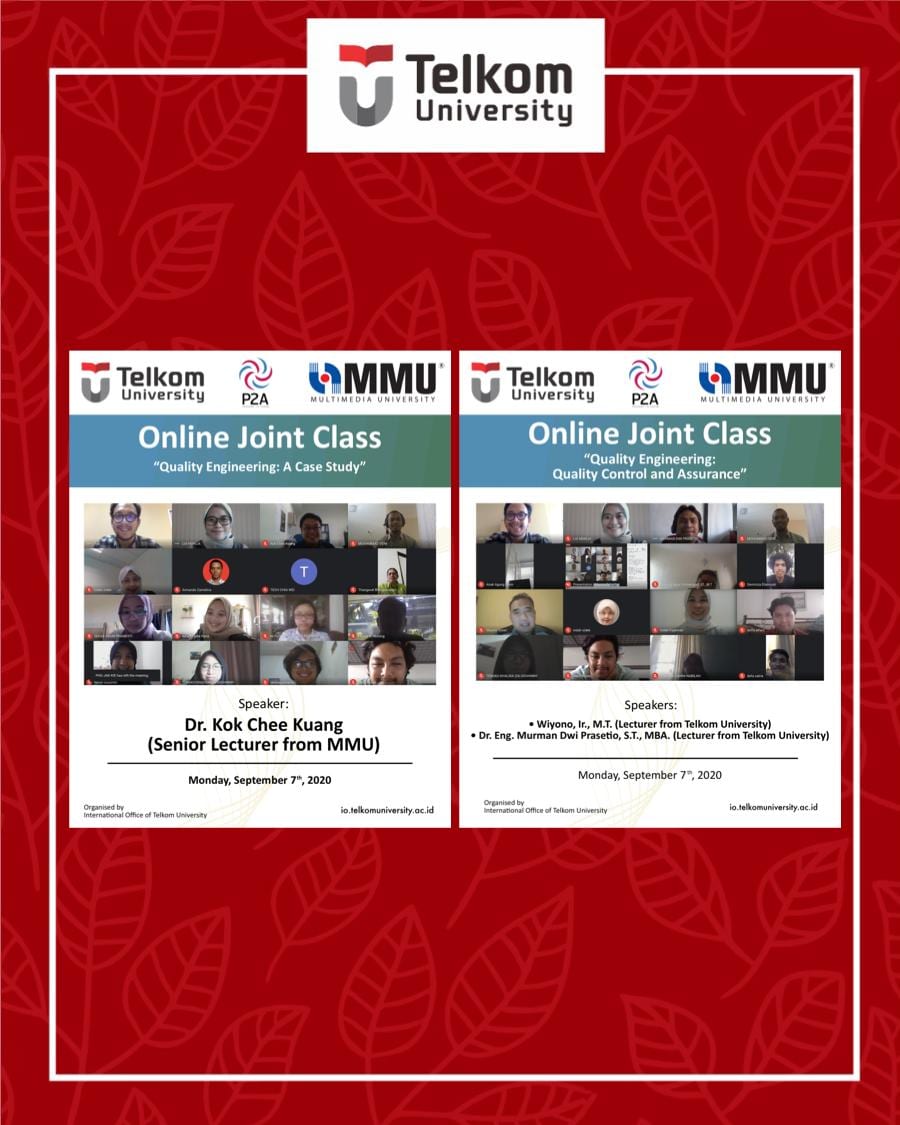

Quality Engineering, the 10th & 11th Online Joint Class Tel U & MMU

Quality Engineering, the 10th & 11th Online Joint Class Tel U & MMU. Today (7/9/2020), the 10th and 11th session of the Online Joint Class between Telkom University, Indonesia and Multimedia University Malaysia (MMU) were carried out smoothly. The 10th session scheduled at this morning at 10 am, presented Dr. Kok Chee Kuang, a senior lecturer from MMU who explained about “Quality Engineering: A Case Study”. Dr. Kok started the class by employing the online survey through menti.com. This survey was aimed to see participants’ readiness or the basic knowledge of the participants regarding the material would be given today. From the survey, almost all participants are familiar with engineering techniques.

Dr. Kok shared about a buzzing speaker case as a case study of the quality engineering. The speaker of the day consist of gasket (rubber), bobbin with VC (copper wire wrapped on paper roll), yoke (cold rolled steel), basket (cold rolled steel), sub-magnet, pole piece (soft iron), main magnet (NdFeB), and diaphragm (polyethylene napthalate, PEN). To investigate why the speaker is rubbing/buzzing, several methods are applied. Firstly, we have to define the problem effectively to gain necessary management support for resources. Remember, a problem well defined is a problem half-solved. Thus it means that if we can accurately find out the problem we hopefully will solve them easily. After knowing the problem, then continue to make a measurement such as a preliminary investigations by doing observation. We can use ISHIKAWA (FISHNONE) and Measurement System Analysis as the important tools.

For observation, we can try to compare the normal speaker to abnormal speaker motion under high speed camera. We can also test the component level test to figure out the right suspects. Here are some possibility of the buzzing speaker:

- Non-concentric diaphragm and basket

- Yoke burr

- Rocking excursion

- Missing dot glue

- Basket deformation

- Jig wear-causing concentricity problem

- Lead wire, copper wire coil, paper bobbin, and non-circular VC, and so on.

In the 11th session scheduled at 1.30 pm, Wiyono, Ir., M.T., a lecturer of Telkom University, and Dr. Eng. Murman Dwi Prasetio, S.T., MBA., a lecturer of Telkom University explained about “Quality Engineering: Quality Control and Assurance”. Quality control is a process of reviewing the quality of all factors involved in production, while Quality assurance is a process of preventing mistakes and defects in manufactured products and avoiding problems when delivering products or services to customers.

There are several aspects need to be checked before mass production to see its quality, including the product base, manufacturing base, transcendental base, service base, value base, and etc. For instance, in term of product base, we can evaluate product characteristics including reliability, operability, durability, maintainability, repair ability, compatibility, and portability.

One of the methods introduced by Dr. Eng. Murman is Taguchi method. The concept of Taguchi is designing products with minimal loss and optimal value. Because, according to Taguchi, 1949, cost is more important than quality but the quality is the best way to reduce the cost. There are three types of noise factor:

- External

It deals with external factors such as load conditions, temperature, humidity, dust, supply voltage, vibrations due to nearby machinery, and human errors in operating the product. - Manufacturing Imperfection

It includes the variation in the product parameters from unit to unit. - Deteriorations

When the product is sold, all its performance characteristics may be right on target, but as years pass by, the values of individual components may change which lead to product performance deteriorations.

In conclusion, quality engineering is very important process to determine the quality of a product so that the product is ready and fit for production, while quality control and quality assurance are very important to gain consumer trust and satisfaction of the products.(IO)***